How To Launch Your Own Gel Polish Brand: Step-By-Step Guide

But let’s not pretend this is “just picking colors” and ordering pretty bottles.

I’ve watched first-time founders get hypnotized by a good-looking sample, then get wrecked on the first real production batch because the viscosity drifts after shipping, the pigments settle weird, and the cure profile doesn’t match what customers actually use at home (365–405 nm lamps, all kinds of wattages, some sketchy), which turns your launch into a refund festival that you can’t “brand voice” your way out of. It happens. Often.

And here’s the ugly truth: most “new” gel polish brands aren’t brands. They’re packaging projects with a Shopify theme.

So if you want to start a gel polish brand and not get laughed out of the room by salon buyers—or eaten alive by chargebacks online—read this like a risk memo, not a vision board.

Table of Contents

Step 1: Decide what you’re selling (because “gel polish” is not a strategy)

Three lanes. Pick one.

If you’re building DTC, you’re selling a look and a vibe, and you live or die on content velocity, fast restocks, and packaging that photographs clean under harsh lighting. If you’re selling to salons, you’re selling repeatability: self-leveling behavior, predictable soak-off, and that boring thing nobody posts about—batch-to-batch consistency.

And if you’re doing private label gel polish, say it with your chest. Private label isn’t shameful. What’s shameful is acting like you “invented” chemistry when your only instruction is “make it more milky.”

Step 2: Get your compliance timeline straight before you touch paid ads

Yet founders love skipping this part. Because it feels slow.

In the U.S., the Modernization of Cosmetics Regulation Act (MoCRA) pushed real operational requirements into the open—facility registration and product listing aren’t optional “later” tasks if you’re selling into that market, and FDA has published deadlines and process guidance that you can’t hand-wave away. I’d rather you read the primary sources than trust somebody’s thread: FDA MoCRA registration & product listing deadline explainer (June 13, 2024) and FDA guidance on registration and listing (Dec 2024).

Do you need to personally become a compliance officer on day one? No. Do you need to know what your supply chain must support—and what proof you can demand? Absolutely.

Step 3: Choose a manufacturer like you’re buying a control system

A real gel polish manufacturer gives you paperwork that’s painfully unsexy.

Batch records. Traceability. COA cadence. Spec ranges that don’t magically change after you pay the deposit. When I’m vetting a supplier, I don’t care about the factory video first—I care about whether they can explain how they control inputs, mixing, filling, and rework without turning it into a mystery novel.

If you want a baseline for how a supplier should present capability, start with OEM/ODM gel polish manufacturing services and then go straight to the part most people ignore: quality assurance and batch control.

And yeah—I’ll say it. Your first factory is rarely your final factory. The goal is “stable enough to scale,” not “perfect forever.”

Step 4: Shade strategy: don’t drown yourself in dead SKUs

I’ve seen founders launch 72 colors and then cry over inventory.

Because they didn’t build a system. They built a wall of choices.

A practical launch edit usually looks like:

- 8–12 core shades (reorderable, reliable sellers)

- 2–4 seasonal drops (controlled risk)

- a base/top system that makes the whole line perform

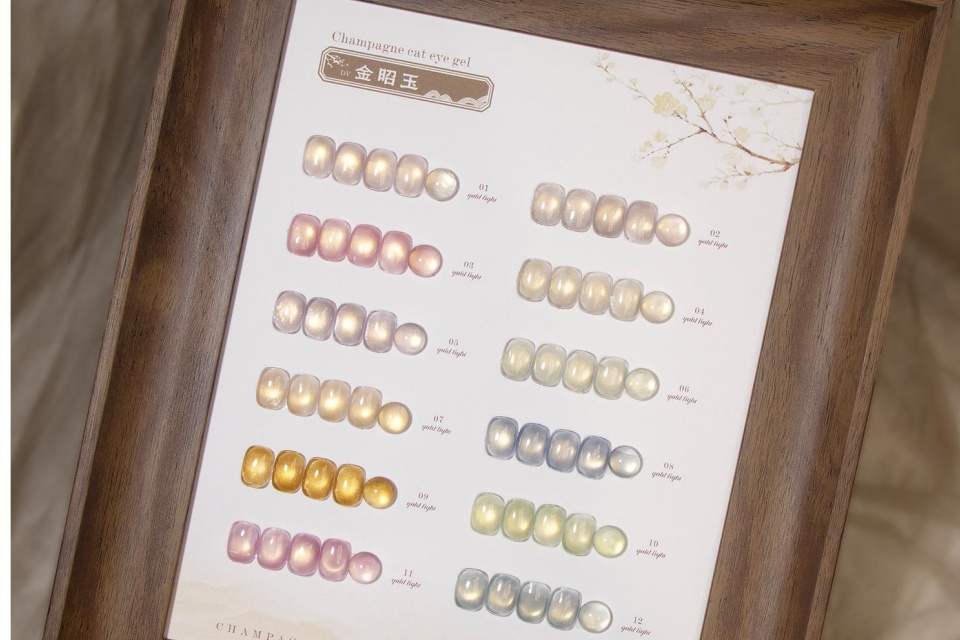

If you need a planning grid, use a catalog as a mapping tool (undertones, finish types, coverage behavior), not a shopping spree. Example reference point: gel polish catalog for shade planning.

Step 5: Safety isn’t a marketing claim. It’s a liability schedule.

So here’s my unpopular opinion: a lot of brand language in nails is playing chicken with reality.

A 2024 retrospective study out of Amsterdam UMC looked at allergic contact dermatitis linked to acrylate-containing nail cosmetics (gel nails and gel nail polish). The numbers hit hard: 67 women diagnosed from 2015 to 2023, and 97% had a positive patch test to 2-hydroxyethyl methacrylate (HEMA); consumers were the majority, and professionals showed up heavily too. Read it, don’t paraphrase it: Amsterdam UMC acrylate allergy study (2024, PubMed).

Now UV curing. People treat lamps like they’re harmless desk toys. In 2023, researchers reported DNA damage and mutation patterns after irradiation using nail polish dryers in mammalian cells, with UC San Diego summarizing results like 20–30% cell death after one 20-minute session and 65–70% after three consecutive 20-minute exposures (in cell lines). That’s not “everyone panic,” but it is a signal for better guidance and safer-use messaging: UC San Diego summary of the 2023 UV nail dryer findings and the underlying paper: Nature Communications (2023).

So what does a serious founder do?

You stop making absolute claims. You stop hiding behind “clean” vibes. You design for less skin contact, clearer directions, and fewer “oops” moments at the cuticle.

Step 6: Packaging is where cheap brands get exposed (fast)

But packaging isn’t “design.” Packaging is performance.

Brush wobble. Neck leakage. Caps that crack. Labels that smear after a wipe with solvent. Bottles that look cloudy in studio lighting (and your ads are basically studio lighting forever). This is where “gel polish branding and packaging” stops being mood boards and turns into engineering.

If you want a controlled example of a set-style offer (useful for merchandising and gifting math), look at: 6-color ombre effect gel polish collection box.

Step 7: Cost math (no fantasies, no influencer budgets)

People always ask how much does it cost to start a gel polish brand.

Here’s my answer: it costs more than you think, and less than you fear—until you ignore reorders, freight delays, and the cash you need to fix issues without going broke.

Also, your “unit cost” is a trap. Landed cost wins. Freight, duties, rejects, replacements, packaging reprints, and customer support time—those are real costs, too.

Here’s a simple reality-check table I’d put in front of any founder before they print labels.

| Launch Model | SKUs & Units (Example) | Typical Spend Buckets | What usually goes wrong |

|---|---|---|---|

| “Proof of Demand” private label | 12 shades × 200 pcs = 2,400 units | Packaging + freight + basic content + small promo | Inventory stuck in slow shades; inconsistent viscosity between shades |

| Salon-first pro line | 24 shades × 500 pcs = 12,000 units | Better packaging + sampling + educator seeding + reorder cash | Reorders slip; salons churn if your base/top system isn’t reliable |

| DTC brand with drops | 10 core + 6 seasonal × 800 pcs avg = ~12,800 units | Studio visuals + paid media tests + fulfillment setup | CAC spikes; returns rise if cure/finish expectations aren’t managed |

One more hard truth: systems beat singles.

It’s not sexy. It’s money. If you want to lower burn and raise repeat purchase, build around the staples early: base coat gel category and top coat gel category.

Step 8: Launch with a control plan, not a prayer

I’ve seen this movie: the first batch lands, the founder posts a launch teaser, then the complaints start—tacky cure, pigment shift, separation, heat spike comments, brush issues—and suddenly you’re doing crisis comms instead of building a business.

So set the controls before you ship:

- Incoming checks (viscosity, color, odor, cure behavior)

- Retention samples per batch

- A complaint log that turns into actions (not excuses)

If your supplier can’t support that rhythm, you don’t have a manufacturing partner—you have a risk generator. Read this carefully and ask for proof: quality assurance and batch control.

FAQs

How do I start a gel polish brand if I’m using private label? Private label gel polish means you launch under your own brand using pre-developed formulas and standardized packaging options from a manufacturer, while you control labeling, shade selection, positioning, and distribution; you’re buying speed and repeatability, not inventing chemistry from scratch. After that, validate demand, negotiate MOQs, and tighten QC.

How much does it cost to start a gel polish brand? The cost to start a gel polish brand is the total of your first production run (units × landed cost), packaging tooling/printing, compliance work (labels, required listings where applicable), freight, and launch spend, with cash reserved for reorders; it’s driven mainly by MOQ and how quickly you must replenish best sellers. Build a budget that survives delays.

What should I ask a gel polish manufacturer before paying a deposit? A gel polish manufacturer is a supplier that produces UV/LED curable nail gel products with repeatable specs, traceability, and quality controls; before you pay, verify factory role (not trading), MOQs, lead times, COA cadence, stability expectations, and the exact process for handling batch issues and reorders. If they won’t document it, assume it’s not real.

Is “HEMA-free” gel polish safer, and should I claim it? HEMA-free gel polish means the formula excludes 2-hydroxyethyl methacrylate, a common acrylate allergen associated with gel product sensitization, but “safer” depends on the full acrylate system, user behavior, and labeling accuracy; a claim is only defensible if you have formulation documentation and you avoid implying medical outcomes. Be careful with absolutes.

What’s the biggest launch mistake in gel polish branding and packaging? Gel polish branding and packaging is the system of bottle, brush, label, and messaging that must survive solvent exposure, handling, shipping, and photo scrutiny; the biggest mistake is optimizing for looks while ignoring leakage, label durability, brush quality, and clear use instructions, which turns into refunds and reputation damage fast. Pretty doesn’t fix defective.

Conclusion

If you want to move from “idea” to “factory-ready,” map your first 10–24 SKUs, lock your reorder plan, and set your QC checks—then talk to a manufacturer with real OEM capability and documented control. Browse the product scope here: gel polish product options and when you’re ready to pressure-test MOQs, lead times, and packaging, use this: contact the gel polish manufacturing team.